SPECIFICATIONS:

@ 25°C ±1°C

Excitation: 10 Vdc

Full Scale Output:

30 mV typical, 26mV minimum

Zero Balance: 0.0mV, +3 mV, -0 mV

Input & Output Resistance: 2000 Ω

minimum, 3000 Ω maximum

Insulation Resistance: 500 megohms

minimum @ 45 Vdc between any

connection and case over the calibrated

temperature range

Sensing Element: 4 active-arm bridge

Gages are sputtered-deposited on the

pressure summing diaphragm

Linearity: ±0.15% FSO maximum

measured best fit straight line through

all data points

Hysteresis: ±0.06% FSO (max) at

constant temperature for a complete

pressure cycle

Long Term Stability: Zero and

sensitivity stability is better than ±0.1%

over a six month period when the

transducer is operated within the

specified environment

Operating Temp Range:

PX3425: -54° to +121°C

(-65° to +250°F)

PX3435: -54° to +177°C

(-65° to +350°F)

Compensated Temp Range:

PX3425: -18° to +121°C (0° to +250°F)

PX3435: -18° to +177°C (0° to +350°F)

Thermal Effects:

(Over the compensated range)

Span: ±0.03% FSO/°F

Zero: ±0.03% FSO/°F

Vibration Sensitivity: At 35g peak

sinusoidal vibration from 10 Hz to 2000

Hz (1/2 ” D.A.) , the output shall not

exceed 0.003% FSO/g

Natural Frequency: >50,000 Hz

Shock: Qualification level of 100g,

11 msec half sine wave without damage

Temperature: Platinum resistance

device to DIN43760 (alpha = 0.00385

½/ohm/°C). See ordering box for

resistance at 0°C (32°F)

Proof Pressure: 1.5 times rated

pressure or 25,000 psi whichever is

less, will not cause the performance to

shift beyond the specified tolerances

Burst Pressure: 2.0 times rated

pressure or 30,000 psi whichever is

less, will not cause rupture of the

pressure containment cavity.

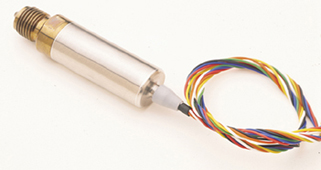

Wetted Parts: 17-4 PH Stainless Steel

Electrical Connection:

7 separate PTFE insulated stranded

wires 25" ± 2" (0.6m ± 0.05m) in length

Pressure Fitting:

9/16 -18 UNF-2A (Mates

with Autoclave F250C or Sno-Trik 44F)

Weight:

4 oz (114g) max including cable

Calibration Record:

OMEGA’s Calibration record is supplied.

Also documented is the pre-ship output

at atmospheric pressure and the

temperature sensor resistance at

25°C ± 2.8°C (77°F ± 5°F)

Options: Special electrical and

pressure connections. Special testing

and calibration procedures. Higher

operating temperatures.

CLOSE

CLOSE