Data Logger

What is a data logger?

A

data logger (or datalogger) is an electronic device that is used to store data over time, commonly known as data logging. This includes many data acquisition devices such

as plug-in boards or serial communication systems which use a computer as a real time data recording system. Nowadays, wireless transmitters are also

capable of turning a regular smart phone (or tablets) into a mobile logger.

A data logging device is often battery powered for use

where no electrical supply exists, data loggers accept one

or more sensor inputs, sampling and saving the data at a

predetermined frequency. This could be as fast as several

hundred per second or as slow as several hundred per day

(and faster and slower data loggers are available).

What is a data logger used for?

Data loggers are used wherever there is some advantage in

recording conditions over a period of time. Applications range

from obtaining a record of wind speed to

tracking temperature

in refrigerated storage containers, to monitoring flow rate at a

remote pumping station. At the end of the acquisition period

the device is retrieved and the data downloaded into a PC

for analysis. Alternatively, data loggers are available that

will wirelessly transmit measurement results to a

PC with a data logging software installed.

Find the

Data Logger for your application using our selection tool.

Learn more about Data Loggers

Types of Electric Signal available for logging

- AC Voltage/Current

- DC Voltage/Current

- Light On/Off

- Shock/Acceleration

- Bridge/Strain/Load/Pressure

- Motor On/Off

- Sound

- Dew point

- PH

- Pressure

- Temperature

- Event or State

- Process Voltage/Current

- Thermistor

- Frequency

- Relative Humidity

- Thermocouple

- Level

- RTD

Data loggers benefit users in two ways. They avoid the time

and expense of sending someone to take measurements in a

remote location, and they enable much higher data density

than is achievable through manual recording, providing higher

quality data.

Many different types of data loggers are available. They range

from single channel devices with the sensor incorporated, to

multi-channel loggers capable of acquiring from diverse

sensors for extended periods. Data logging software provides

the ability to configure acquisition parameters and format data

outputs.

How to choose a Data Logger?

Most data loggers are general purpose devices although

some are optimized for a specific type of sensor connection

and reading (temperature being the most common). A data

logging equipment may be selected for one particular task or as an

addition to an inventory of data acquisition hardware. In either

case, the needs of the intended or likely application(s) should

be considered with regard to the following capabilities.

How do data loggers work?

A general purpose multi-channel data logger will usually

accept both analog and digital inputs. Examples of analog

inputs include temperature, pH and humidity. Note that analog

inputs may be either single or double-ended (differential).

Using differential sensors halves the number of analog inputs

available. An example of this would be a

multi channel temperature logger for thermocouples.

Two examples of digital inputs are those from a

wind speed sensor or a paddlewheel-style flow sensor. Some

types of data logger are designed for specific types of sensor

input such as thermocouples or atmospheric sensors (such as

barometric pressure and humidity).

Number of Inputs

Data loggers divide into two types: those that accept only

a single sensor input (and that sensor may or may not be

integrated into the unit), and those that can be connected to

a number of sensors simultaneously. While a single channel

data logger may be sufficient for some applications the

multi-channel data logger is a more versatile device. Multichannel

loggers are available with as many as 32 inputs

(depending on how the device and sensors are configured).

However, the most commonly used type is the 4-channel

data logger as this provides a good combination of storage

capacity, battery life (where used) and compact size.

Size

In many applications space is a limitation. In those cases the size of the portable data logger may be a critical selection parameter.

OMEGA's OM-CP family of data loggers are extremely compact and include models for most input types. Submersible devices are also available for

marine and aquatic applications.

Speed/Memory

Data logging systems are available with sampling rates as high as

200 kHz while at the other end of the spectrum some can set

to sample once in 24 hours. When evaluating sampling rate

requirements note that memory capacity is a fixed number of

data points. Thus sampling at a higher frequency fills available

memory quicker. Some logger devices handle memory overload by

wrapping around and overwriting, which means older data is

lost.

Real Time Operation

In general a data logger writes each measurement point to

memory for retrieval later. However, some have the ability to

output measurement results as they are taken. Look for this

feature when it is important to see “live” measurement data.

Data Download

There are several ways of retrieving measurement results from

a data logging system. For a simple USB data logger all that’s required

is to collect it from the field and plug it into a PC. Data logging

software is available to streamline the download process and

assist with formatting for Excel® or other packages. If physically

visiting the data logger is undesirable but a wired connection

is feasible, alternatives are the serial data logger and

the

RS232 data logger. When running wires out to a remote data

logger is infeasible the solution is to use a wireless data logger

that transmits data to a receiver connected to a PC.

Key Aspects to Consider When choosing a logging system

- Input Signal

- Number of Inputs

- Size

- Speed/Memory

- Real Time Operation

Why Choose a Data Logger Over Other Types of Data Collection Instruments?

Three types of instruments are commonly used for collecting and storing data:

- Real-Time Data Acquisition Systems

- Chart Recorders

- Data Loggers

Other ways of logging measurement data are the chart

recorder and the real-time data acquisition system. Until the

development of the data logger the chart recorder was the

predominant instrument. These typically require pens and

specialized paper. Moreover, the data cannot readily be

moved into a PC for mathematical or statistical analysis.

Real-time data acquisition systems offer flexibility but also

require a direct computer connection. This limits their use in

situations where data is to be acquired in a remote location

or where portability is a consideration. For example, a realtime

data acquisition system would not be feasible in logging

temperatures inside refrigerated shipping containers.

Data logger uses

Miniature Single Input Data Loggers

Miniature Single Input Data Loggers

Miniature single input data loggers are generally low cost devices dedicated to a specific input type. These types of data loggers

are often used in the transportation industry. A typical application would be to include a temperature data logger in a shipment of

food products to insure that the food temperature does not exceed acceptable limits. In addition to temperature miniature data loggers

are available for a large variety of input types. most input types.

Fixed Mount Multi-Channel Data Loggers

Fixed Mount Multi-Channel Data Loggers

Fixed input loggers have a fixed number of input channels which are generally dedicated for a specific type of input.

OMEGA offers fixed input data loggers ranging from one to 8 channels.

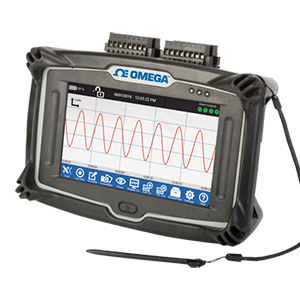

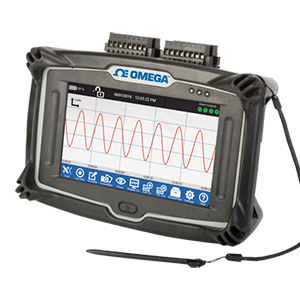

Handheld Multi-Channel Data Loggers

Handheld Multi-Channel Data Loggers

Handheld multi-channel loggers are commonly used in applications where the data logger is to be carried from one location to another.

They are also commonly used in benchtop or laboratory environments. In addition to storing data internally some models even contain on board

printers which can produce an immediate hardcopy of the data.

Modular Data Loggers

Modular Data Loggers

A modular data logger is configurable and expandable through the use of plug-in modules. The modules are normally field configurable and the

user has the option of adding as many channels to satisfy the application requirement.

Frequently Asked Questions

What are the Main Advantages of Data Logging?

A data logger provides the ability to take measurements in

any location, even during transit, without human intervention.

Furthermore, measurements can be closely spaced to capture

transient events or far apart to maximize recording duration.

Another advantage of data loggers is that

the data can then be easily transferred to a PC for analysis

and formatting. This significantly reduces the work required to

make measurements while allowing for increased data density

when needed.

Do Data Loggers Need to be Connected to a Computer?

No, some data loggers provide an option for real-time display but all OMEGA data loggers collect data independently of the computer.

What is the Maximum Sample Rate for a Logger?

The sample rate depends on the specific model. Although most data loggers have a maximum data rate of 1 or 2 samples per second, OMEGA offers a number

of data loggers that can sample in excess of 100 samples per second.

How are the logging equipment Powered?

Most data loggers are battery powered some also offer an option for external power.

How Long Does the Battery Powered Logger Last?

The battery life depends on a number of parameters including the specific model and sample rate. In general the faster the sample rate the

shorter the battery life. Many OMEGA data loggers feature a battery life as long as ten years.

Will the Data Logger lose its Data if the Power or Battery Fails?

Most OMEGA data loggers use non-volatile memory for data storage. This means that the data will not be lost if the power fails.

How Long Can the devices Record Data?

The recording duration is dependent on the memory capacity of the data logger and the desired sample rate. To determine the duration divide the memory

capacity(number of samples the device can record) by the sample rate. As an example assume that a given data logger

can store 10,000 samples. If it is desired to record 2 samples every minute, the system can run for 10,000/2 or 5,000 minutes(about 3.5 days).

If the sample rate was cut in half(1 sample per minute), the recording period would double to 7 days.

Data Logger | Related Products

↓ View this page in another language or region ↓

CLOSE

CLOSE

Registradores de Dados

Registradores de Dados Enregistreurs de Données

Enregistreurs de Données Registradores de Datos

Registradores de Datos Registradores de Datos

Registradores de Datos Data Loggers

Data Loggers Dataloggere

Dataloggere Enregistreurs de Données

Enregistreurs de Données Datenlogger

Datenlogger Registratori di Dati

Registratori di Dati Data Loggers

Data Loggers Datalogger

Datalogger Data Loggers

Data Loggers Data Loggers

Data Loggers Data Loggers

Data Loggers

データロガー

データロガー 데이터로거

데이터로거 Data Loggers

Data Loggers

Data Loggers

Data Loggers

Data Loggers

Data Loggers

Data Loggers

Data Loggers

Data Loggers

Data Loggers