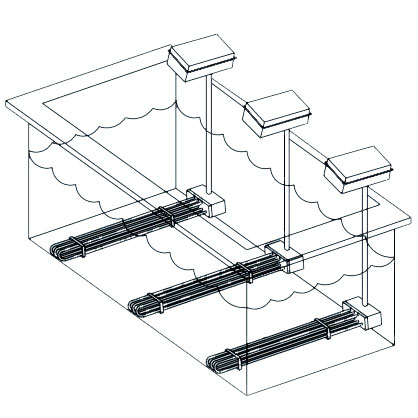

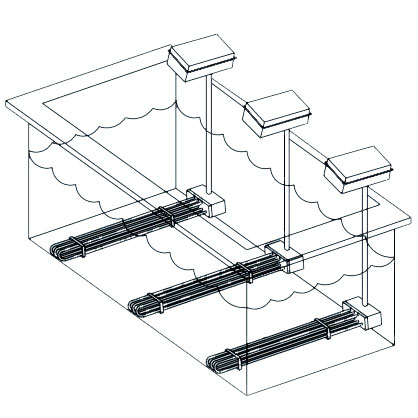

Over-the-Side Immersion Heater

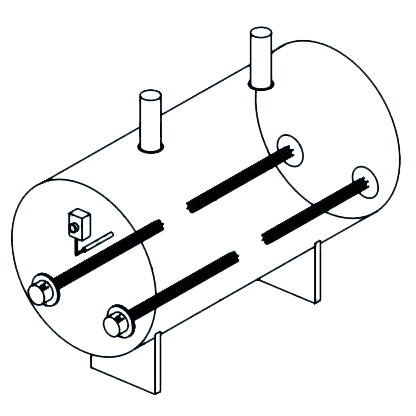

Over-the-side immersion heaters are designed for vessels where through the side submersible heaters cannot be conveniently installed.

The best way to use these heaters is installing those through the top of the vessel with the heated portion of the unit along the side or at the bottom of the tank.

Natural circulation of the fluid inside the tank allows for even distribution. Terminal houses or lead wires are provided for power connection.

The immersion heater element is installed in the top

of a tank with the heated portion

directly immersed along the side or

at the bottom. This provides easy

removal of the heater and ample

working space inside the tank.

These heaters are available with heating elements made of copper, steel, stainless steel, cast iron, Incoloy, titanium, and PFA coated. A wide

selection of kilowatt ratings, shapes and mounting methods are available to suit many different types of applications.

The large variation in inmmersion heating element material and shapes of over-the-side immersion heaters offers a wide selection in the application of these

units. Water, oils, solvent, plating baths, salts and acids are some of the many liquids and viscous materials commonly heated with immersion

heaters. Over-the-side types permit portability, easy removal for cleaning of tanks and heaters, and ample working area within the tank when installed.

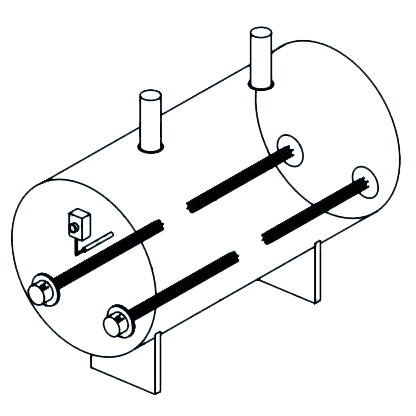

Flanged Immersion Heaters

Flanged immersion heaters consist of hairpin bent tubular elements welded or brazed into a flange and provided with wiring boxes for electrical

connections. Flange heaters are installed by bolting to a matching flange welded to the tank wall or nozzle. A wide selection of flange sizes,

wattages, voltages, terminal housings and sheath materials makes these heaters ideal for all types of heating applications.

Flanged immersion heaters are one of the most widely used methods for heating liquids (such as water, oil, heat transfer fluid and corrosive

solutions). Designed for use in tanks and pressurized vessels, they are easy to install and maintain to provide heat for many processes. The

direct immersion method is energy efficient and easily monitored and controlled.

A thermostat protective well is

standard on most models. This well

is installed through the flange

parallel with the heating elements

This 1/2" thermowell is provided for

accepting a temperature sensing

probe for use with a thermostat

or other type control

system.

Flexibility of the type of control

can be provided to give exact process

control precision to match your

process needs.

These electric immersion heaters utilize standard pipe flanges ranging from 3" to 14" in diameter to support high tank pressures of

liquids. They are installed through a matching companion flange, obtainable from local industrial supply houses, to the tank wall. A wide

selection of watt densities, heating outputs and flange sizes and ratings make this an excellent heater for all tanks, vats or irregularly

shaped vessels.

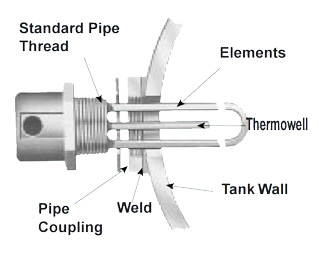

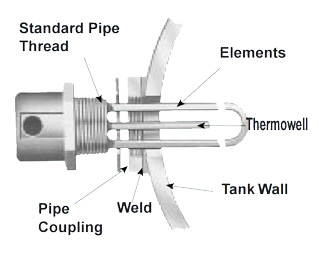

Threaded or Screw Plug Immersion Heaters

Screw plug immersion heaters consist of hairpin bent tubular elements brazed or welded into a screw plug and provided with wiring boxes

for electrical connections. Screw plug immersion heaters are screwed directly through a threaded opening in a tank wall or through matching

pipe coupling, half coupling or welding flange. Sizes of screw plug heaters are available with ½", ¾", 1", 1¼", 2" and 2½" pipe threads. A

wide selection of screw plug sizes, kilowatt ratings, voltages, sheath materials, terminal housings, and thermostats makes these compact

heaters ideal for all types of applications.

This type of electric immersion heaters are used for heating liquids in a variety of processes. Those heaters are ideal for process water heating

and freeze protection. All types of oils and heat transfer solutions can also be heated using these compact easily controlled units. The

direct immersion method is energy efficient and well suited for many applications.

The heavy duty tubular

elements are welded or brazed to a

screw plug. Uniform heat

distribution and repressed element

bends provide long element life.For

heaters with built-in thermostats, a

thermowell (hollow tube sealed at

one end) is welded or brazed to the

screw plug and allows thermostat

sensing element replacement

without draining the tank.

Screw plug heaters are equipped

with a steel enclosure, and are also

available with a combination

moisture resistant/explosion

resistant enclosure.

The heater element is screwed directly through a threaded

opening in tank wall. Heavy tank

walls may be drilled and tapped if

thickness is sufficient to engage 3/4 of

threads. Lighter tank walls should

be equipped with suitable pipe halfcoupling

attached with proper braze

or weld material.

Thermostats or Temperature Control

Many screw plug and flanged type heaters are available with built-in thermostatic controls. In some installations, where there is more than one

heater in a tank, you may consider one heater with a built-in control that will control the other heaters by wiring thermostat into the holding

coil circuit of a magnetic contactor.

If the thermostat is separate from the heater, the thermostat sensing element should be located approximately

4 to 6 inches above the heater.

Other

types of controls are available where a high degree of accuracy or a more versatile control scheme is required.

Electronic controls and complete control panels are easily installed.

CLOSE

CLOSE

Aquecedores de Imersão

Aquecedores de Imersão Éléments Chauffants à Immersion

Éléments Chauffants à Immersion Immersion Heaters

Immersion Heaters Thermoplongeur

Thermoplongeur Tauchheizkörpern

Tauchheizkörpern Immersion Heater

Immersion Heater Immersion Heater

Immersion Heater Immersion Heaters

Immersion Heaters 浸入式加热器

浸入式加热器 Immersion Heaters

Immersion Heaters

투입 히터

투입 히터 Immersion Heaters

Immersion Heaters

Immersion Heaters

Immersion Heaters

Immersion Heaters

Immersion Heaters

Immersion Heaters

Immersion Heaters

Immersion Heaters

Immersion Heaters