A Strain gauge (sometimes refered to as a Strain gage) is a sensor whose resistance varies with applied force; It converts force, pressure, tension, weight, etc., into a change in electrical resistance which can then be measured. When external forces are applied to a stationary object, stress and strain are the result. Stress is defined as the object's internal resisting forces, and strain is defined as the displacement and deformation that occur.

The strain gauge is one of the most important sensor of the electrical measurement technique applied to the measurement of mechanical quantities. As their name indicates, they are used for the measurement of strain. As a technical term "strain" consists of tensile and compressive strain, distinguished by a positive or negative sign. Thus, strain gauges can be used to pick up expansion as well as contraction.

The strain of a body is always caused by an external influence or an internal effect. Strain might be caused by forces, pressures, moments, heat, structural changes of the material and the like. If certain conditions are fulfilled, the amount or the value of the influencing quantity can be derived from the measured strain value. In experimental stress analysis this feature is widely used. Experimental stress analysis uses the strain values measured on the surface of a specimen, or structural part, to state the stress in the material and also to predict its safety and endurance. Special transducers can be designed for the measurement of forces or other derived quantities, e.g., moments, pressures, accelerations, displacements, vibrations and others. The transducer generally contains a pressure sensitive diaphragm with strain gauges bonded to it.

Learn more about

strain units and the history of the gauge sensors.

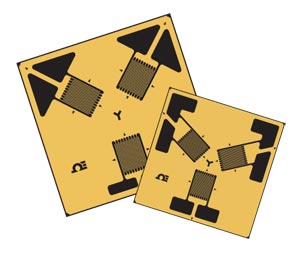

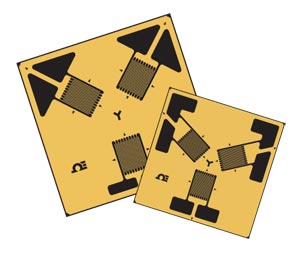

General Purpose Precision Strain Gauges

General purpose precision strain gauges are encapsulated constantan foil strain gauges offered in a wide variety of patterns for scientific, industrial and experimental stress analysis. These precision strain gauges can be used for experimental stress analysis monitoring industrial equipment or various scientific applications. In the General purpose strain gauge section you will find the strain gauge patterns next to the part numbers so that you will be able to see the geometry of the strain gauge. The gauge dimensions are also provided in and SI (Metric, mm) and US Customary (English, inches) units. General purpose precision strain gauges are offered in linear patterns, dual parallel- grid patterns, Tee rosettes (0/90°), rectangular or delta (45° or 60°), stacked or planar rosettes, and shear patterns.

Transducer Quality Strain Gauges

Transducer-quality strain gauges are for customers who are manufacturing transducers or similar sensing devices. Transducer-quality strain gauges feature a tighter tolerance on the carrier trim dimensions which allows the carrier edge to be used for strain gauge alignment if required. They also feature tighter tolerances on nominal resistance values. These gauges can be creep adjusted to meet a transducer manufacturer's

strain gauge specifications and they can be customized to the unique requirements of a transducer. They are also excellent gauges off-the- shelf for experimental stress analysis and/or strain verification projects.

Karma Strain Gauges

Strain Gauge Selection Considerations

- Gauges Length

- Number of Gauges in Gauge Pattern

- Arrangement of Gauges in Gauge Pattern

- Grid Resistance

- Strain-Sensitive Alloy

- Carrier Material

- Gauge Width

- Solder Tab Type

- Configuration of Solder Tab

- Availability

Omega offers a full line of Karma Strain Gauges. Karma Strain gauges can be used for various static and dynamic applications. Karma strain gauges are used for transducer applications where long term stability or higher temperature use is required. When used at room temperature, for static strain measurements, the transducer will have very good stability for months or even for years. Karma strain gauges are also suggested for static strain measurement over a wide temperature range from -75 to 200°C (-100 to 392°F) due to its good linearity over this wide temperature range. Karma strain gauges are often used for fatigue-rated transducer designs. T e fatigue life of Karma alloy tends to be much better than constantan, and so transducers using Karma strain gauges provide good fatigue life. Karma is a nickel-chromium alloy, and was selected as a strain gauge material for it’s modulus-compensating capabilities which tends to significantly reduce span shift in transducer design.

With Karma alloys, the gauge factor tends to decrease with increasing temperature. This effect of decreasing elastic modulus will tend to reduce the span shift. Karma alloys do have drawbacks, for example they are difficult to solder without special fluxes. OMEGA has the solution. We have eliminated this problem by offering our Karma Strain Gauges with copper plated solder pads. No special flux or procedures are needed.

Bonded Foil Strain gauges

The first bonded, metallic wire-type strain gauge was developed in 1938. The metallic foil-type strain gauge consists of a grid of wire filament (a resistor) of approximately 0.001 in. (0.025 mm) thickness, bonded directly to the strained surface by a thin layer of epoxy resin. When a load is applied to the surface, the resulting change in surface length is communicated to the resistor and the corresponding strain is measured in terms of the electrical resistance of the foil wire, which varies linearly with strain. The foil diaphragm and the adhesive bonding agent must work together in transmitting the strain, while the adhesive must also serve as an electrical insulator between the foil grid and the surface. When selecting a strain gauge, one must consider not only the strain characteristics of the sensor, but also its stability and temperature sensitivity. Unfortunately, the most desirable strain gauge materials are also sensitive to temperature variations and tend to change resistance as they age. For applications of short duration, this may not be a serious concern, but for continuous industrial measurement, one must include temperature and drift compensation.

Pre-Wired Strain Gauges

Pre-Wired Strain Gauges

Strain Gauges for Shear or Torque Applications

Strain Gauges for Shear or Torque Applications

Extra-Long Grid Pattern for Inhomogeneous Materials

Extra-Long Grid Pattern for Inhomogeneous Materials

Sensores de Deformação

Sensores de Deformação

Jauges de Contraintes

Jauges de Contraintes

calibradores de tensión

calibradores de tensión

calibradores de tensión

calibradores de tensión

Strain Gages

Strain Gages

Belastningsmålere

Belastningsmålere

Jauges de Contrainte

Jauges de Contrainte

Dehnungsmessstreifen

Dehnungsmessstreifen

Estensimetri

Estensimetri

Strain Gauges

Strain Gauges

Galgas extensiométricas

Galgas extensiométricas

Strain Gauges

Strain Gauges

Strain Gauges

Strain Gauges

应变计

应变计

Strain Gauges

Strain Gauges

ひずみゲージ

ひずみゲージ

스트레인 게이지

스트레인 게이지

Strain Gauges

Strain Gauges

Strain Gauges

Strain Gauges

Strain Gauges

Strain Gauges

Strain Gauges

Strain Gauges

Strain Gauges

Strain Gauges