What is a Mineral Insulated Cable?

A Mineral insulated cable (MI cable) is a specialized type of cable used in high temperatures or harsh environmental conditions because it has low flammability, even when operating at high temperatures. It resists oxidation and enables precise measurement.

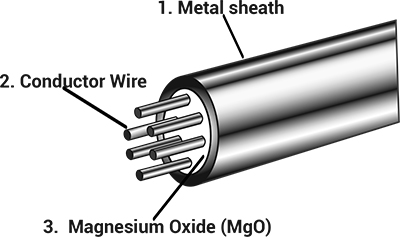

A Mineral insulated cable (MI cable) is a specialized type of cable used in high temperatures or harsh environmental conditions because it has low flammability, even when operating at high temperatures. It resists oxidation and enables precise measurement. MI cable consists of copper wires inside a copper, stainless steel, or Inconel® sheath, insulated by packed minerals such as magnesium oxide (MgO). Magnesium oxide makes an excellent electrical insulation material because it resists oxidation and ionizing radiation, and it is both chemically and physically stable at high temperatures. After the MI cable has been packed with MgO insulation, it may be rolled under pressure to achieve the desired diameter. The outer sheath protects the internal thermocouple wire from heat, chemical or other environmental damage. The metal sheath may be covered with an additional colored plastic sheath to add in identification and to add an additional layer of protection from corrosion.

An MI cable may contain any number of wires, but the most common configurations include 1, 2 or 3 pairs of conductors. Specialized MI cables may include additional thermocouples in customized configurations. Mineral insulated cable is available in a variety of diameters and lengths, depending on the specific requirements. Many MIcables are calibrated using sensitive, fast and highly accurate dry block probe calibrators.

Temperature sensors manufactured from Mineral insulated cable, such as some RTDs or thermocouples, are used extensively in heat treating metals, solid waste incinerators, sintering powdered metals, firing ceramic materials, gas or oil fired furnaces, fuel fired heat exchangers, box furnaces and nuclear or hydrocarbon based energy plants.

What are the advantages of mineral insulated cables

The mineral fillings in MI cables provide excellent non-reactive insulation, preventing the thermocouple wires from contact with each other or with caustic substances such as oils, solvents or water. This helps to ensure that the thermocouple probes remain accurate, critical in applications such as heat treating or sintering where the quality of the product could be adversely affected by temperature fluctuations.

The insulation in Mineral insulated cables does not burn, which makes it ideal for applications where fire could be catastrophic. Medical devices, power plants and oil rigs are examples of places where installation of MI cables makes operations safer.

Since the thermocouple probes are protected from contact with other electrically active wires by the insulation, they are not readily subject to malfunction or inaccurate temperature measurements. Carefully calibrated to meet international standards, MI cables provide accurate and precise temperature measurement over long duty cycles with little or no loss of accuracy.

Because of the mineral insulation, MI cables can operate in high temperature conditions with no loss of accuracy. This makes them ideal for kilns, firing ceramics or heat treating metals or in any high temperature process. MI cables retain their accuracy even during and after exposure to high temperatures, so they are ideal as a temperature probe in these operations. In addition, for industries such as medical devices or aerospace where safety standards are strictly enforced, process deviations could result in life threatening quality issues. Mineral Insulated cables are carefully calibrated and verified using NIST standards at OMEGA Engineering against known temperatures or certified thermometers. NIST traceable calibration ensures temperature accuracy under actual operating conditions and provides documentation of their original accuracy. To remain NIST certified, the chain of verification must be intact and the thermocouples must be recalibrated as part of a well-documented and executed quality management system.

CLOSE

CLOSE

Omega's relationship with Rutgers sprouted with their goals in substituting manual processes with an IoT solution for hands-off data collection capabilities.

Omega's relationship with Rutgers sprouted with their goals in substituting manual processes with an IoT solution for hands-off data collection capabilities.

MI cables are used in high temperature or high pressure harsh environments for a good reason, here's why:

MI cables are used in high temperature or high pressure harsh environments for a good reason, here's why: